Training Contents

- Scientific fundamentals of radiographic testing The genesis of X-rays and gamma radiation

- Attenuation and energy selection

- Films and transparencies

- Geometrical recording conditions

- Film processing and viewing

- Image quality factors / determination of image quality

- Specimen-specific inspection techniques

- Weld seams and seam defects

- Quality requirements for welds

- Weld seam defects in the radiographic testing image

- Factors influencing image contrast

- Image resolution and distortion

- Checking the recording equipment

- Techniques for evaluating radiographic images

- Evaluation based on bodies of standards

- Specimen or object contrast and radiation contrast

- Film system and film contrast

- Perceptibility of details and determination of image quality

- Area susceptible to evaluation, distortion and circumference of specimen

- Special radiation sources, recording techniques and radiation receivers

- Evaluation of radiographic images

- Casting and casting defects

- Evaluation of radiographic recordings of castings

- Weld seams and seam defects

- Evaluation of radiographic images of weld seams

- Fundamentals of digital radiology

- NDT Lab Reporting

About the course

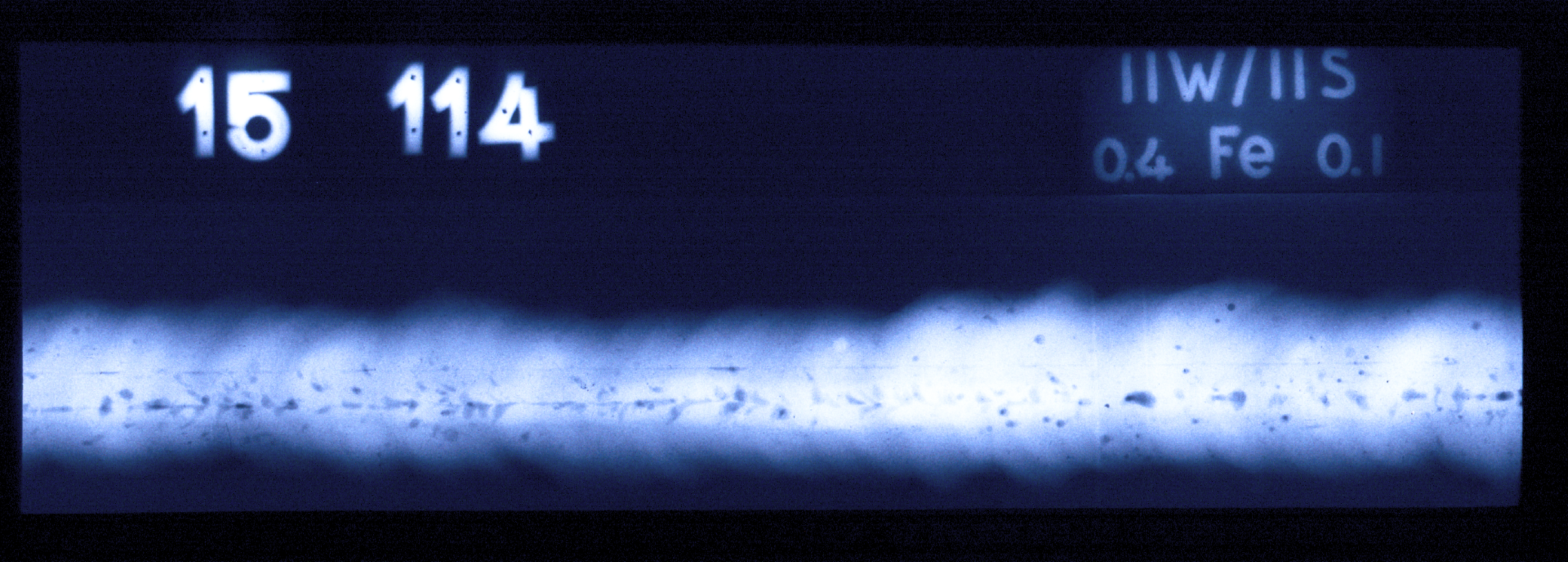

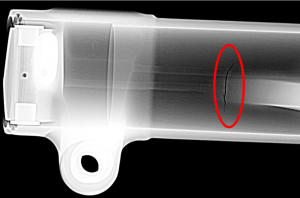

Radiography is a Non Destructive Testing carried out using X-ray generators or artificial gamma sources. X-rays or gamma rays pass through the object to be radiographed and record an image on a radiographic film, placed on the opposite side. The quality and amount of radiation reaching the film will be largely determined by the objects thickness and density, e.g. a crack in a weld will increase the amount of radiation falling on the film in that area due to a reduction in thickness. When the film is processed a negative is produced. The thin areas of an object will be darker than the thicker areas, therefore most weld defects will show up dark in relation to the surrounding areas. Radiography Course contains the Basic Radiation Safety (BRS), the Radiographic Interpretation (RI) and Radiographic Testing (RT). Radiography can be used for inspection of welds, castings and wrought materials, in metallic and non metallic materials.

When the film is processed a negative is produced. The thin areas of an object will be darker than the thicker areas, therefore most weld defects will show up dark in relation to the surrounding areas. Radiography Course contains the Basic Radiation Safety (BRS), the Radiographic Interpretation (RI) and Radiographic Testing (RT). Radiography can be used for inspection of welds, castings and wrought materials, in metallic and non metallic materials.

ABOUT

In industry, employees with great experience and sound production know-how (e.g. welding or foundry technical staff) often evaluate X-ray films without having to record radiographic images on their own. The ability of this group of people to evaluate films can be certified in the form of a limited RT certificate based on EN ISO 9712 (EN 473). The training course consists of film evaluation and film recording. If the candidate attends both parts of the course and passes the examination, an RI (RT certificate restricted to film evaluation) and according to EN ISO 9712 (EN 473) can be issued.

Training Contents

- Weld seams and seam defects

- Quality requirements for welds

- Weld seam defects in the radiographic testing image

- Factors influencing image contrast

- Image resolution and distortion

- Checking the recording equipment

- Techniques for evaluating radiographic images

- Evaluation based on bodies of standards

- NDT Lab Reporting

ABOUT

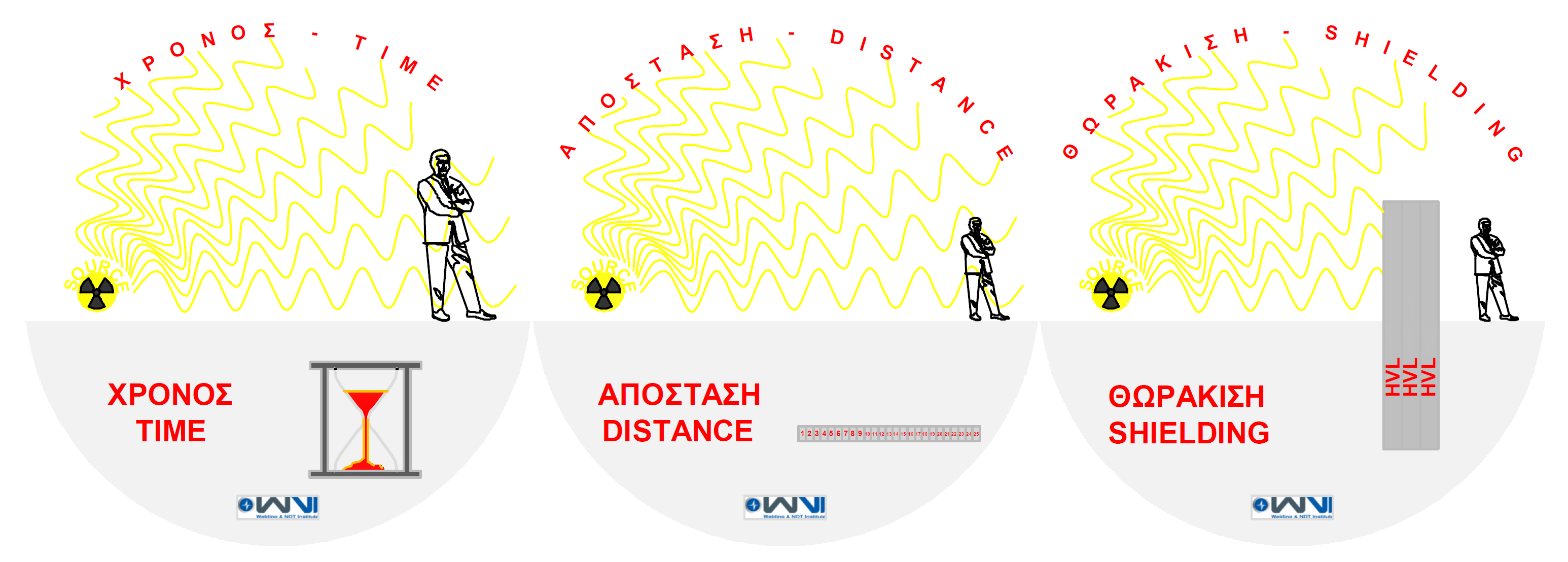

This course is designed for those with very little or no knowledge of radiation safety. The course is suited to those requiring a knowledge of radiation safety including trainees, industrial radiographers, managers and supervisors.

Training Contents

- Basic radiation physics

- Radiographic equipment

- Radiation unitsBiological effect

- Dose limits

- Radiation detection and measurement

- Protection against radiation

- Calculations for radiation protection

- Storage of radiation sources

- Transport of radioactive substances

- Appointments and responsibilities

- Local Rules and contingency plans

- Personal dosimetry

- Normative documents

ABOUT

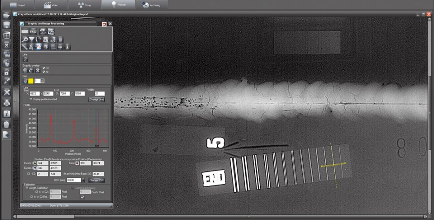

Using this filmless radiography you can carry out radiographic testing without loosing time in the chemical development processes. The X-ray film is replaced by detectors. The images can be archived digitally and processed further. Possibilities of image processing and the use of different filters offer several possibilities to present test results in the best way. In this training course you will learn about and how to use this new technique.

Training Contents

- Scientific base of radiographic testing

- Parameters of digital images (standards)

- Presentation of digital images

- Digital imaging media

- Quality of digital images

- Standards

- Sensitivity of digital systems

- Functions for imaging

- Filter and software components

- Object and software components